In modern industrial production, ton bag packaging machines have become the preferred equipment for large-capacity packaging of powdered and granular materials due to their efficient and precise packaging performance. How does this intelligent and automated packaging solution achieve high-efficiency operations? Let’s take a closer look.

1. The Five Major Systems of a Ton Bag Packaging Machine

The ton bag packaging machine primarily consists of five key systems: the weighing system, lifting system, filling system, dust removal system, and electrical control system. Each system performs its specific function while working in coordination. Additionally, deaeration and compaction features are available as optional configurations.

1.Weighing System: Equipped with four high-precision sensors, it monitors the material weight in real-time and automatically adjusts the filling speed based on weight data to ensure packaging accuracy.

2.Lifting System: Hydraulically driven for smooth operation, it can stop at any height to accommodate ton bags of different specifications.

3.Filling System: Composed of a buffer hopper, rotary valve, pinch valve, and airbag, it fills the ton bag at the preset speed while working with the dust removal system to minimize dust leakage.

4.Dust Removal System: Utilizes dual filtration through an airbag balance pipe and an automatic reverse-pulse dust collector to efficiently capture dust generated during packaging, maintaining a clean working environment.

5.Electrical Control System: Intelligently regulates the entire packaging process, ensuring safe and stable operation according to preset parameters.

II. Core Technical Parameters

1.Weighing Accuracy: ≤1‰

2.Packaging Speed: >3 bags/hour

3.Bag Weight Capacity: 300kg~1000kg/bag (customizable)

4.Air Supply Requirements: Pressure 0.5~1MPa, Air Consumption ≥0.4m³/min (Working Pressure >0.7MPa)

5.Power Supply: 380V 50Hz 8KW

III. Working Process of Ton Bag Packaging Machine

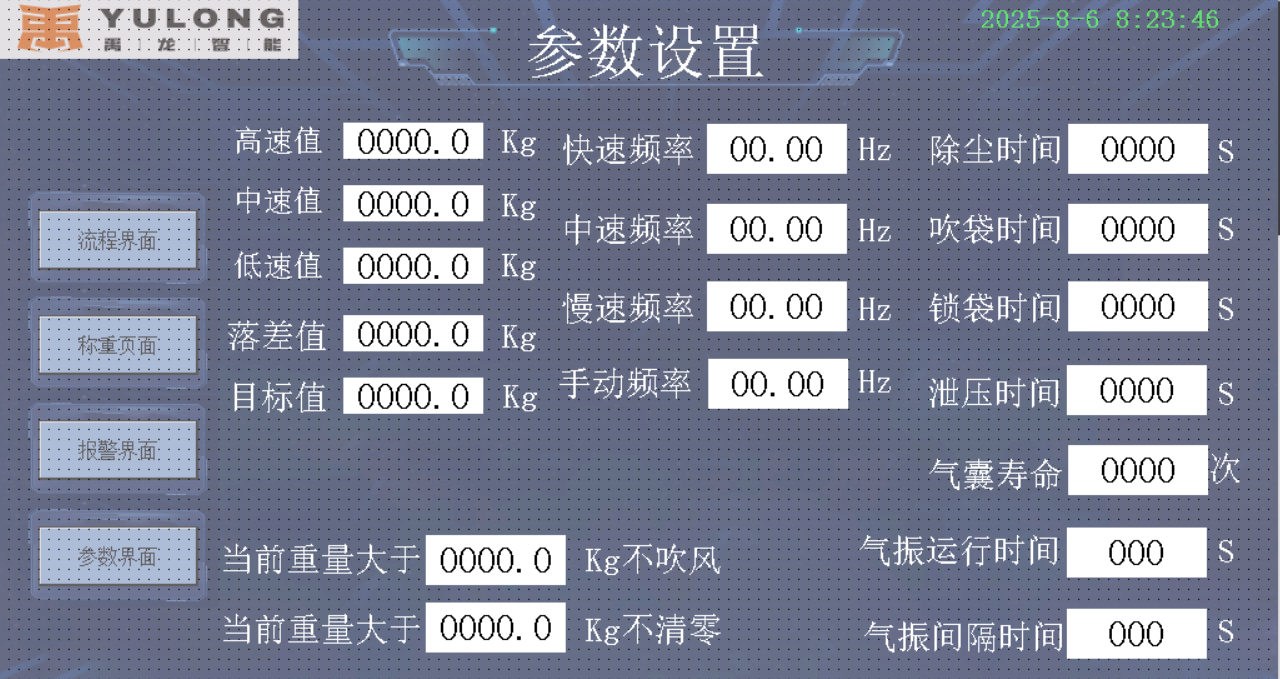

1.Parameter Setting

Set parameters such as single-bag weight, filling speed (fast/medium/slow), bag inflation time, and dust removal time on the touchscreen to ensure the packaging process meets production requirements.

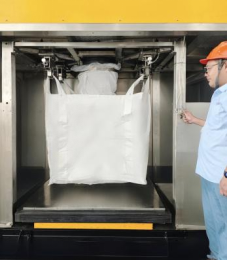

2.Bag Hanging Operation

Lower the lifter to its lowest position.

Manually unfold the empty ton bag and secure the four corner lifting loops.

Thread the inner bag through the airbag ring, then raise the lifter until the bag bottom contacts the platform to complete fixation.

3.Automatic Filling

Upon startup, the airbag inflates to seal the bag mouth while the blower inflates the ton bag for easier filling.

The pinch valve and rotary valve open, feeding material at the preset speed. The weighing system adjusts the feed rate in real-time to ensure accuracy.

The dust collector operates simultaneously to minimize dust emission.

The system automatically stops upon reaching the target weight and awaits bag removal.

4.Effortless Bag Removal

The airbag deflates, and the unhooking mechanism releases the lifting loops.

Workers pull out the filled ton bag manually.

The lifter resets, and forklifts transport the finished product, completing the packaging cycle.

IV. Advantages of Ton Bag Packaging Machine

1.High Efficiency & Precision:

Fully automated feeding and filling process with precise weight control

Dust recovery through the dust removal system ensures 100% material yield

2.Eco-Friendly & Clean Operation:

Dual dust removal design effectively suppresses dust pollution

3.User-Friendly Operation:

Human-machine interface with touchscreen control

Adjustable parameters to accommodate different material requirements

4.Safe & Stable Performance:

Hydraulic lifting + electrical control ensures smooth and reliable operation

Ton bag packaging machines are widely used in chemical, building materials, food, and other industries as an intelligent large-capacity packaging solution.

We provide:

Professional customization services

Full-process technical guidance

Comprehensive after-sales support

Let intelligent packaging empower your business growth!

Welcome to inquire – we'll deliver the optimal ton bag packaging solution for your needs.

The New Era of Smart Packaging:

Precision & Efficiency for a Winning Future!

(Note: I've optimized some phrases for better marketing impact while maintaining technical accuracy. The translation keeps all key information while presenting it in a more natural business-English style.)